Variax

Variax is the name for high-performance high-speed press feeders and peripheral equipment and systems from Sankyo. This series combines our time-proven cam technology with the latest drive technology to solve a various requirements in the press and forming industry. The Variax includes the world's fastest feeder, based on a roller gear cam drive mechanism and an originally developed motion profile and servo drive mechanism. We offer roll feeders capable 2,000 spm and grip feeders capable of 3,600 spm, both the fastest in their class. Both types offer adjustable feed pitch, thickness, grip force, roll parallelism, and other features. These adjustments can be easily done during continuous operation, making the Variax easy to use and suitable for high productivity.

Product Line

OPUS1 Series (High-performance servo feeder)

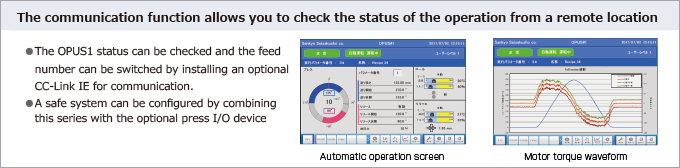

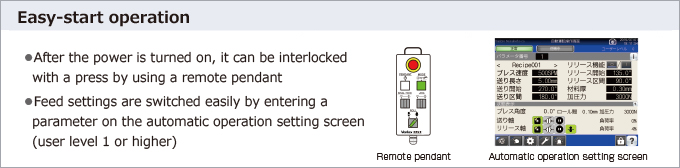

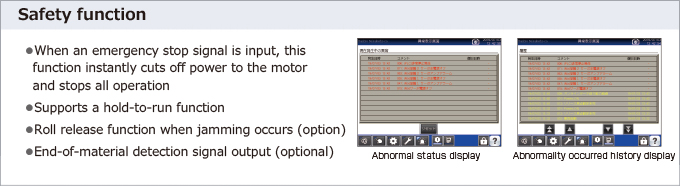

The servomotor is operated according to a unique cam curve. Servomotor and cam curves are also used to control vertical roll motion and the release mechanism, allowing the OPUS series to feed thin and soft materials. The OPUS series control system is also equipped with a monitor function, diagnostic function, anda large monitor. Its communication function makes it possible to check the operation from a remote location. This combination greatly improves its operability.

Features

- High-end model combining high speed, high precision and multiple functions

- The communication function allows you to check the status of the operation from a remote location

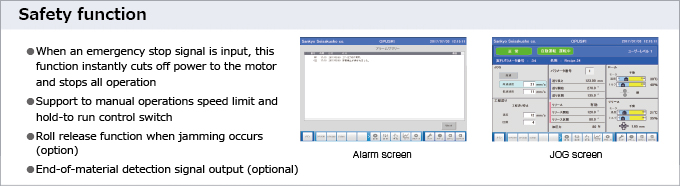

- Excellent operability with a security system

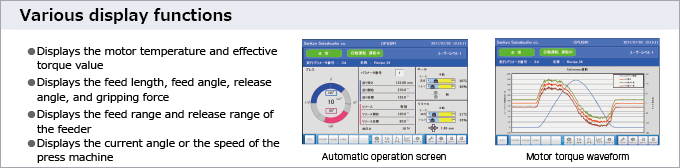

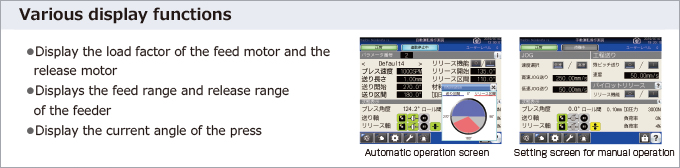

- Various display functions

- Global support for many languages, standards, and services

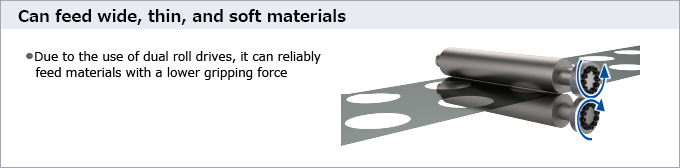

- Can feed wide, thin, and soft materials

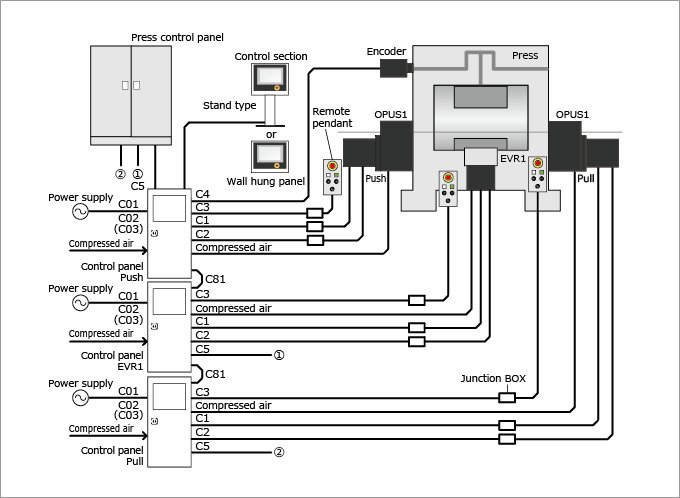

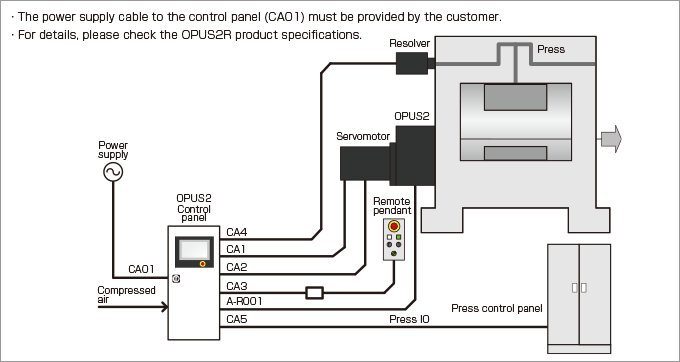

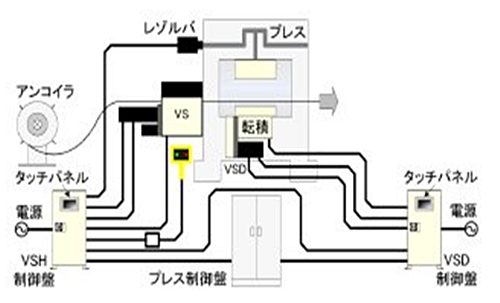

Control configuration diagram

Application

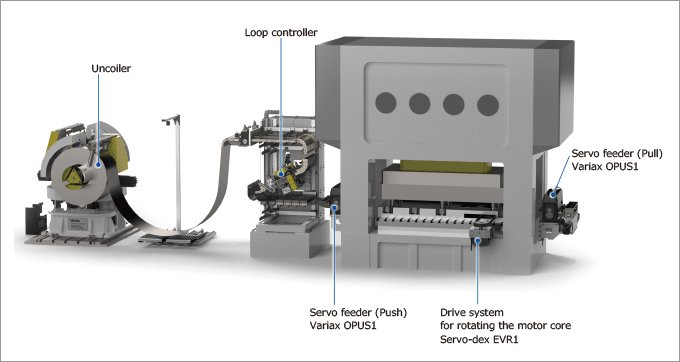

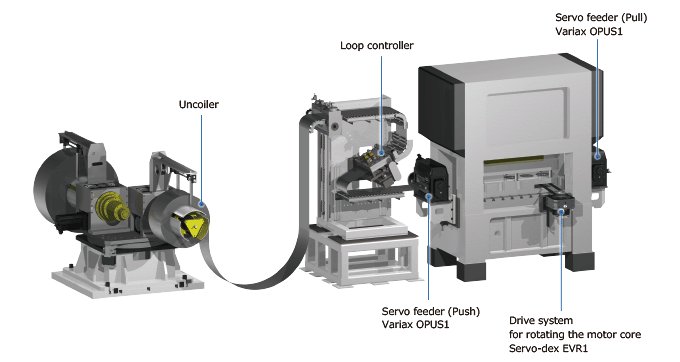

Control configuration diagram(OPUS1×2, EVR1)

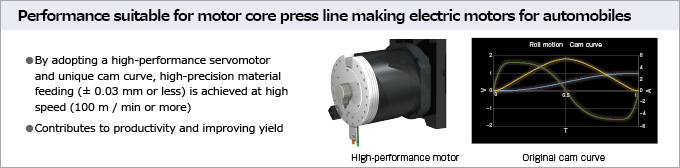

The OPUS1 is a high-performance servo feeder that combines a roll feeder with a high-performance servo motor, further developing Sankyo's proprietary technology, to achieve the world's fastest performance.

The servomotor controls the motion of the upper and lower rolls for feeding material to achieve accurate feeding at high speeds of 120 m/min. The pilot release mechanism uses a servo motor and specialized motion control for accurate synchronization of the push/pull mechanism, allowing the machine to handle thin sheets and soft materials at high speeds.

The servomotor controls the motion of the upper and lower rolls for feeding material to achieve accurate feeding at high speeds of 120 m/min. The pilot release mechanism uses a servo motor and specialized motion control for accurate synchronization of the push/pull mechanism, allowing the machine to handle thin sheets and soft materials at high speeds.

OPUS2 Series (General-purpose servo feeder)

General-purpose servo feeder provides

basic performance at low cost

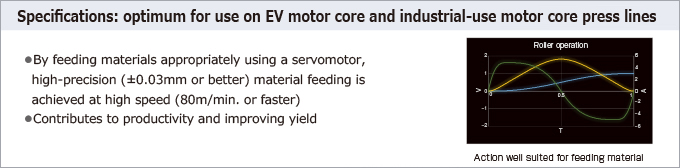

OPUS2 series are servo feeders for presses that are optimized to produce the electric motor cores used in EV motors and other industrial-use motors.

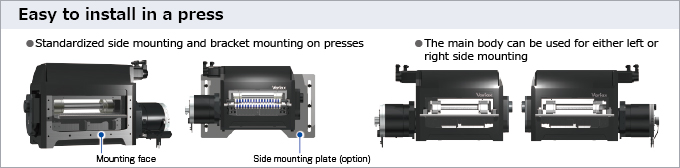

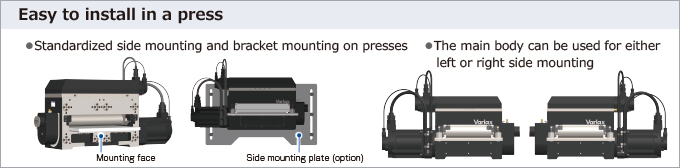

Compared to our OPUS1 series high-end Variax model, this series is lighter and more compact.

Due to the use of dual roller drives, it offers stable material feeding of various materials (wide, thin, or soft materials) with a low gripping force.

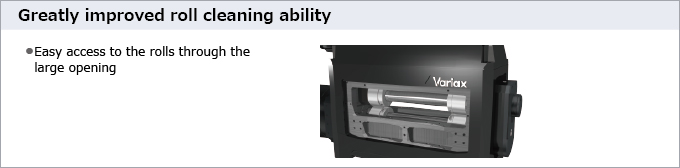

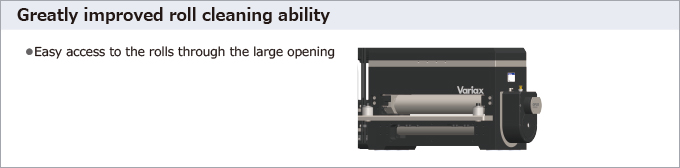

Since the models in this series have a large opening and a detachable lower cover, the rollers can be cleaned easily.

basic performance at low cost

OPUS2 series are servo feeders for presses that are optimized to produce the electric motor cores used in EV motors and other industrial-use motors.

Compared to our OPUS1 series high-end Variax model, this series is lighter and more compact.

Due to the use of dual roller drives, it offers stable material feeding of various materials (wide, thin, or soft materials) with a low gripping force.

Since the models in this series have a large opening and a detachable lower cover, the rollers can be cleaned easily.

Features

- Industry-leading world-class performance level

- Built in preventive maintenance and diagnostic functions for IoT compatibility

- Excellent operability with a security system

- A wide range of display functions

- Global support for many languages and services

- Make it possible to transport a variety of plate materials, including wide, thin, and soft materials, as well as plates up to 5 mm thick.

Control configuration diagram

Application

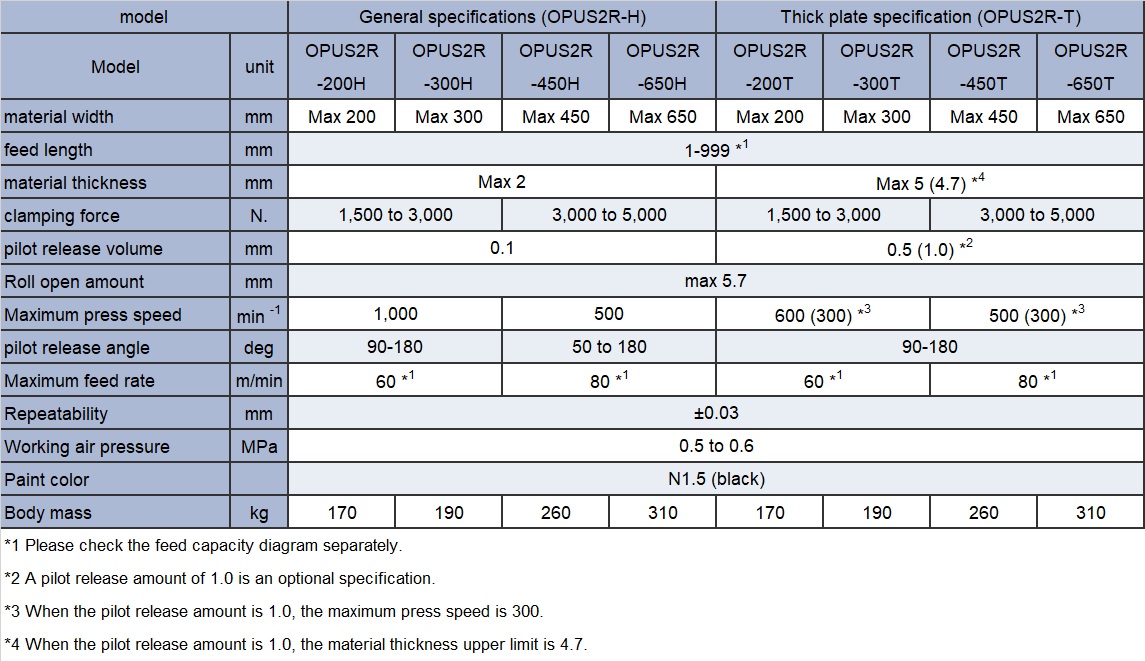

OPUS2 Series Specifications

V Series (Hight-speed & High-precision cam type roll feeder)

V Series is a high-performance cam-actuated variable roll feed that uses fan-shaped sector rolls and four cam mechanisms. It offers unparalleled accuracy and convenient design features for ease of operation and use. Numerous technical innovations have made the V Series the choice feeder for stamping lines all over the world for more 20 years since its inception. Innovations such as dual-driven rolls, parallelism adjustment for the rolls and brake, and an absolute digital counter for precise feed pitch display are just a few examples.

Sankyo has also developed newer models that are even easier to operate and handle while meeting specific needs, such as wide stock handling ability and advanced functionality.

Sankyo has also developed newer models that are even easier to operate and handle while meeting specific needs, such as wide stock handling ability and advanced functionality.

Features

- High Reliability : Cam-actuated for excellent reliability.

- Easy to Adjust : Push button operation for easy adjustment of feed pitch, material thickness, and grip force. Also features parallelism adjustment for rolls and brakes.

- Impressive Installed Base : The V Series has the longest history as an individual feeder with an impressive track record.

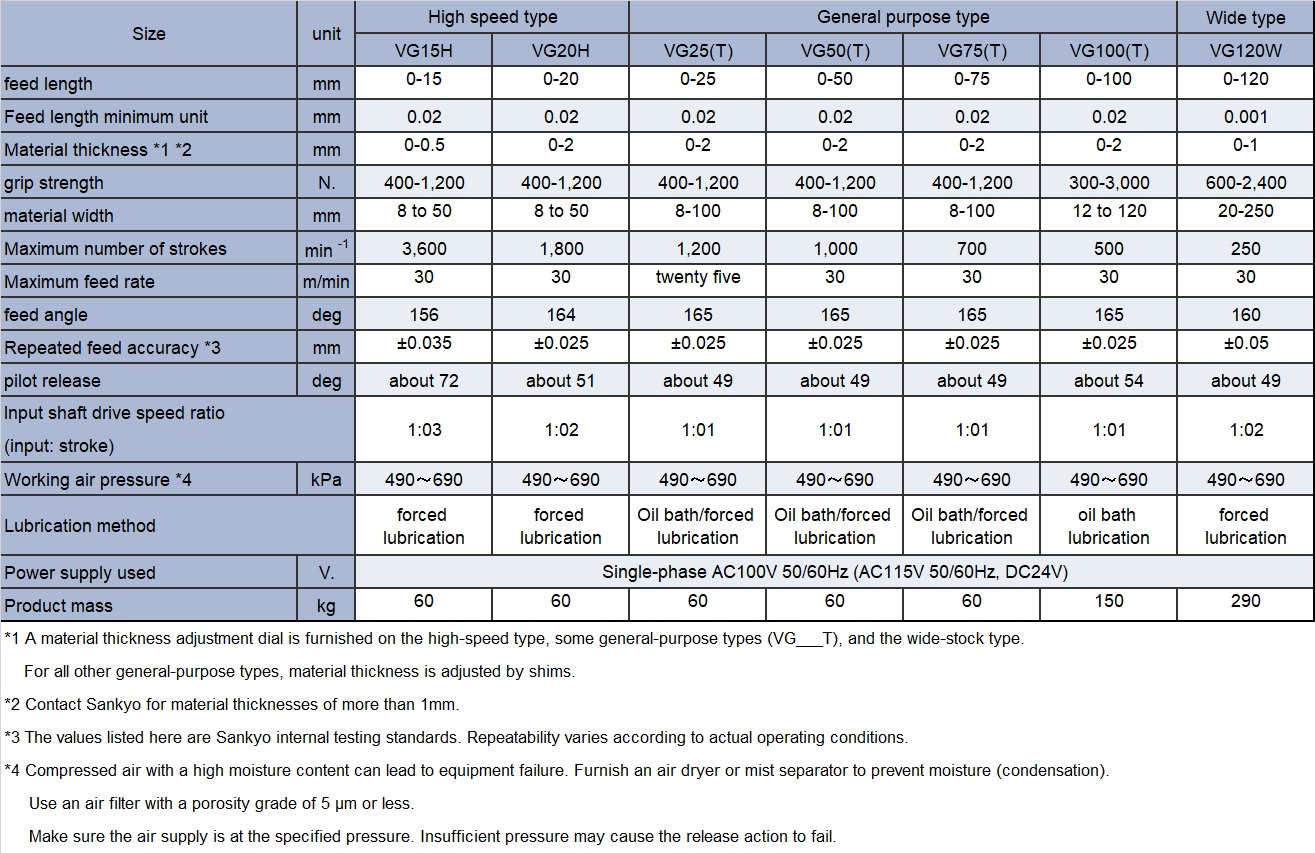

VG Series (General-purpose gripper feeder)

Features

- Wide Product Lineup : Available in a wide range of models and sizes, and designed to meet various feeding conditions.

- Ultra-high-speed Feeding : Capable of ultra-high-speed feeding up to 3,600 spm (model VG15H).

- Easy to Adjust : Easy dial adjustments of feed pitch, grip force, and material thickness (material thickness is adjustable only on the VG__(T)).

- Handles Various Materials : Inherently designed to feed irregularly shaped material, soft material, and processed material.

Example

Connector / Terminal / IC lead frame / Motor core / Wire materials / Bearing parts / Washer / Needle pin / Beverrage can / Stay on tab / Spring parts / Battery parts / Coin cell / Heat sink / Tab tape / Paper tape / Laminate film / FPC /VG Series Specifications

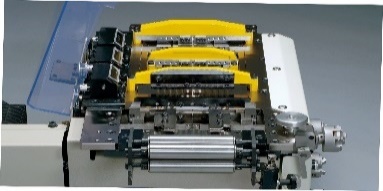

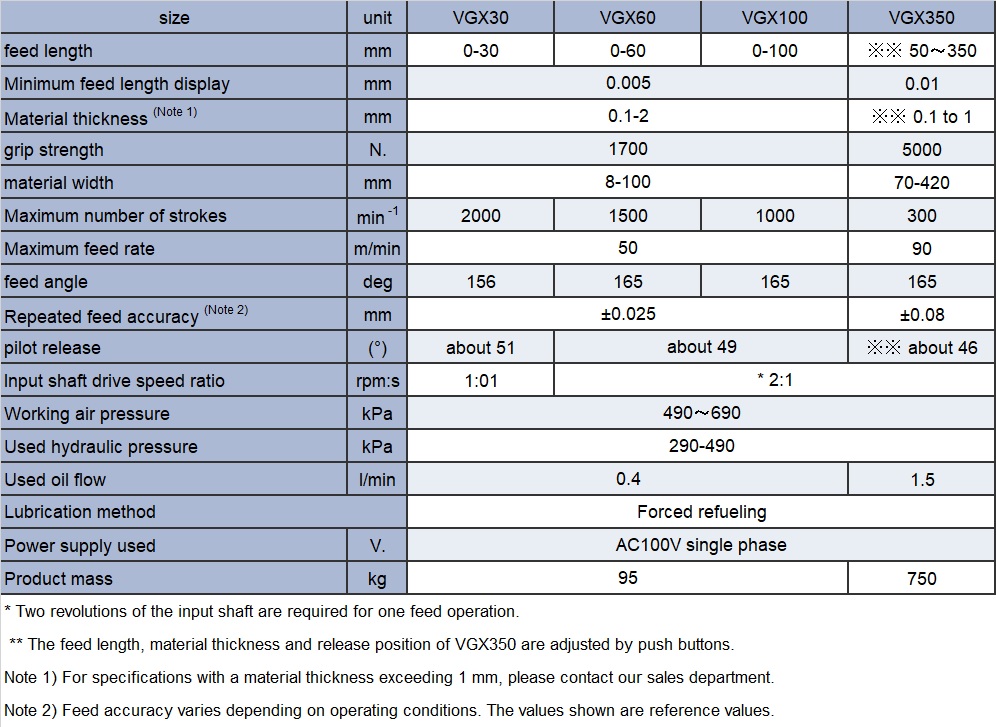

VGX Series (Flexible & ajustable gripper feeder)

Features

- Wide Product Lineup : Available in a wide range of models and sizes, and designed to meet various feeding conditions.

- Ultra-high-speed Feeding : Capable of ultra-high-speed feeding rates of up to 2,000 spm (model VGX30).

- Many Adjustable Features : Adjustment dials used for all adjustments (push buttons used on the VGX350) with digital readout for material thickness and release position.

- Handles Various Materials : Inherently designed to feed irregularly shaped material, soft material, and processed material.ป

Example

Connector / Terminal / IC lead frame / Motor core / Wire materials / Bearing parts / Washer / Needle pin / Beverrage can / Stay on tab / Spring parts / Battery parts / Coin cell / Heat sink / Tab tape / Paper tape / Laminate film / FPC /VGX Series Specifications

VUC Series (Uncoiler)

Offers high-speed, good follow-up control,

and stable material feeding.

It works at high speed and has good follow-up control. The rotating section that winds and unwinds coils of material is driven by a servomotor, so that the feeder supplies the correct amount of material to match the press rotation speed in real time. Also, by installing a movable arm in contact with the outer surface of the coil, the radius can be determined and therefore the amount of material left can be controlled, offering remarkable stability while feeding.

Features

When a coil is attached to the setup side it takes 90 seconds or less to turn it to the production side, automatically insert it into the leveler, and then automatically pass the material through to the feeder.

Adopting our high-rigidity reducer in the mandrel drive unit. It permits a press hot start and provides stable opreration. This feature makes it possible to shorten the distance between uncoiler and leveler. It also contributes to space saving, Becase it doesn't need pits to make buffers.ร์

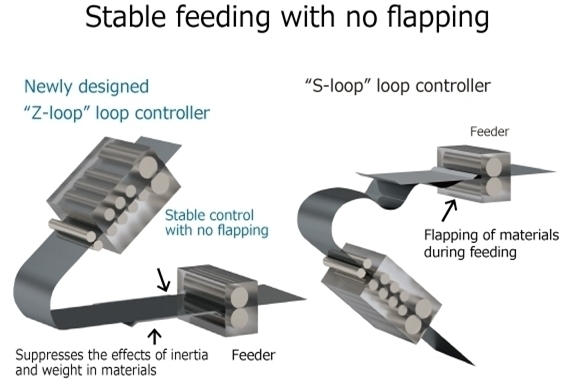

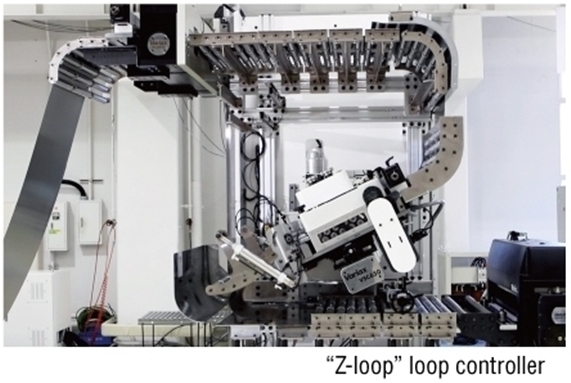

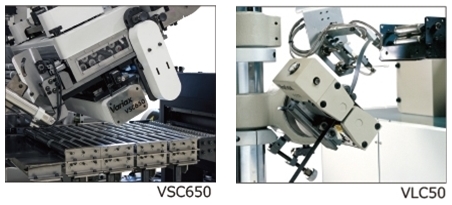

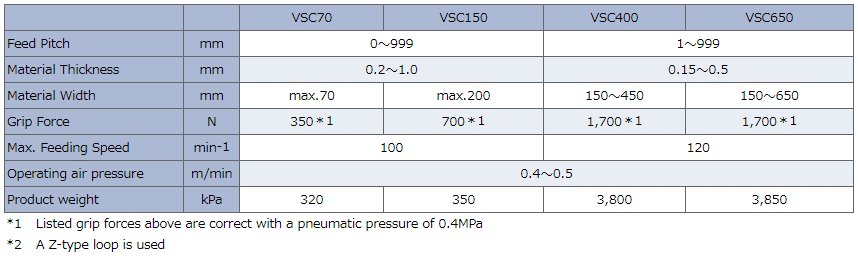

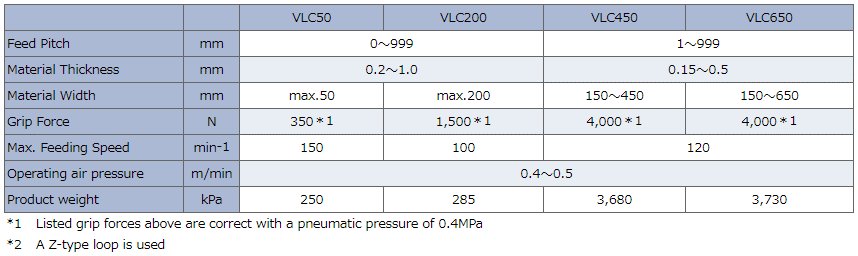

VSC/VLC Series (Loop controller)

The NC Loop Controller is a unique product developed to condition loop stock for material feeding by restricting the material's freedom of motion. No other device works the same way. Servomotors control the amount of rotation of the drive rolls while sensors and our dedicated servo controller stabilizes the loop into an optimum shape. This reduces flapping in all speed ranges. The material is delivered to the feeder without scratches, creases, or markings, thus improving the quality of the finished product and the productivity of the line. Small footprint design makes it easy to install.

Features

- Adopt high-resolution and high-torque servo motor.

- Eliminate bending of the material near entrance loop.

- Available load and unload material at low speed.

- Feed conditions can set up on touch screen.

- Integrating leveler function for remove flatness defects from material.(VSC Series)

- Reduce setup time

Suppresses the flap caused by material feeding and the impact of weight, maximizes the capacity of the feeder, and its excellent stability at high speed operation realizes high quality and even faster feed of thin plates.

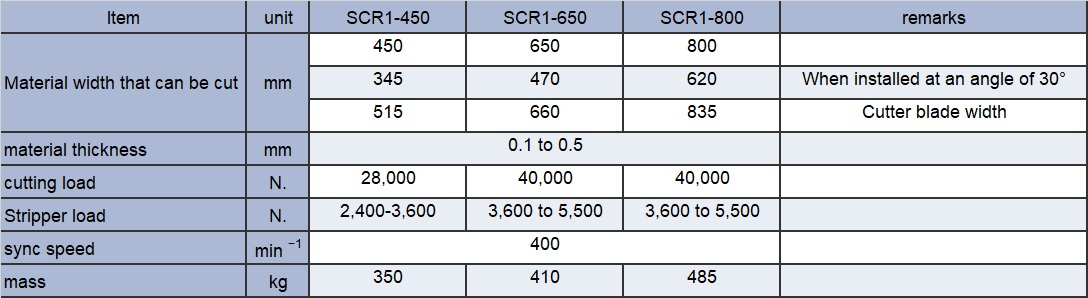

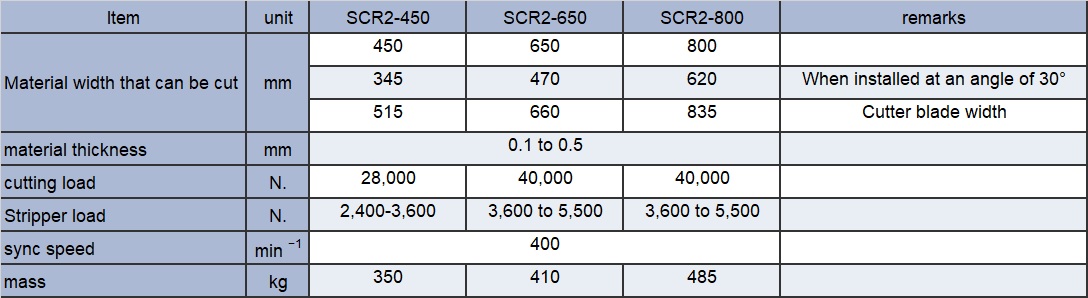

SCR Series (Material cutter)

World's thinnest material cutter

A material cutter developed to achieve high productivity of cores for EV motors. The newly developed camshaft drive structure has achieved an ultra-thin design which enables close mounting to a feeder. Achieves high-speed feeding of skeleton thin-plates, which had been difficult to feed, contributing to increased production efficiency.

A material cutter developed to achieve high productivity of cores for EV motors. The newly developed camshaft drive structure has achieved an ultra-thin design which enables close mounting to a feeder. Achieves high-speed feeding of skeleton thin-plates, which had been difficult to feed, contributing to increased production efficiency.

SCR1 Series |

SCR2 Series |

Features

- Compact : Has the world's thinnest cutter (160 mm). Saves space and speeds up press line operations.

- Stable cutting : It offers stable cutting of thin plate materials thanks to its back stopper.

- Maintenance : Easy replacement of cutting blades.

- Monitoring function : check the motor torque on the monitor while cutting (touch panel)

- Set up position ajustment : The cutting position can be adjusted

Scrap cutter 160 mm wide, ultra-thin, and fully synchronized with the press. This thinness allows for close mounting to the feeder, reducing the trouble caused by conventional products when transferring materials after stamping, and realizing high-speed operation synchronized with the press.

.jpg)

.jpg)

.jpg)

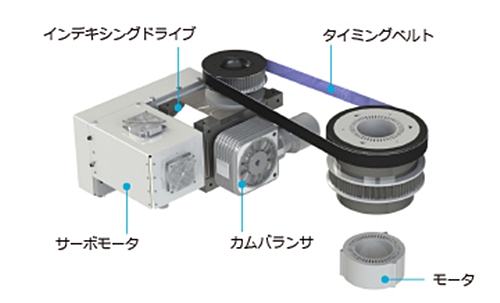

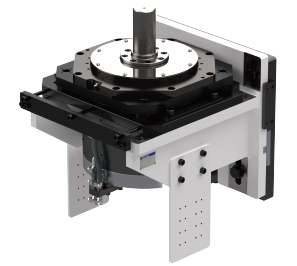

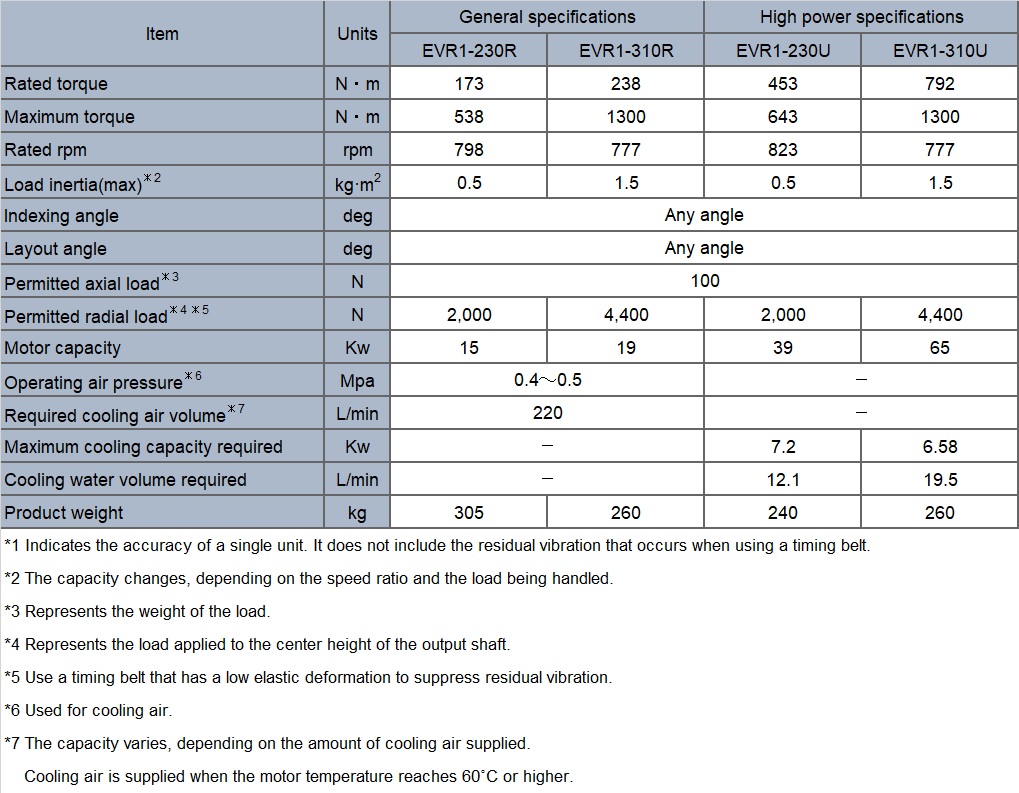

EVR1 Series (Indexing / Skewing drive system for rotating motor core)

Servo-dex EVR1 Series

The Servo-dex EVR1 series is an indexing or skewing drive system for rotating the motor core for production lines making motor cores for hybrid, PHEV, and EV car motors.

By connecting a high-performance servo motor directly to the motor core, it can index core stacks with high-speed and high-torque, while allowing you to set the rotation angle freely.

With fusion of a servo motor and a cam motion curve, high speed and a variety rotational stacking build-ups are possible. This contributes to improved productivity of high-quality motor cores.

By connecting a high-performance servo motor directly to the motor core, it can index core stacks with high-speed and high-torque, while allowing you to set the rotation angle freely.

With fusion of a servo motor and a cam motion curve, high speed and a variety rotational stacking build-ups are possible. This contributes to improved productivity of high-quality motor cores.

Features

High-end model combining high speed, high precision and multiple functions

Built in preventive maintenance and diagnostic functions to support IoT compatibility

Built in preventive maintenance and diagnostic functions to support IoT compatibility

.jpg)

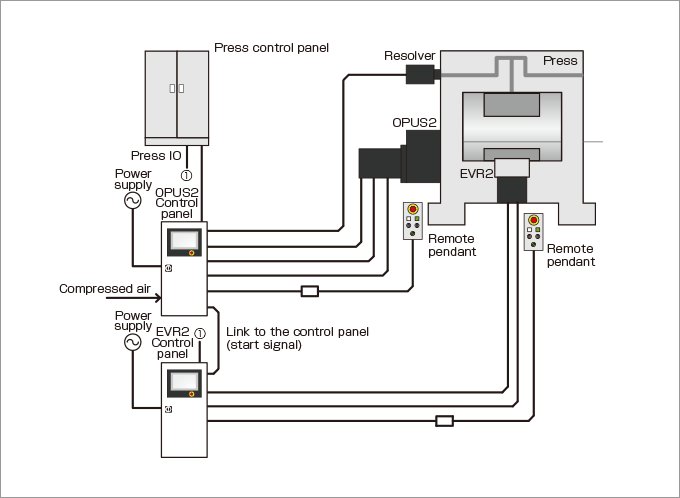

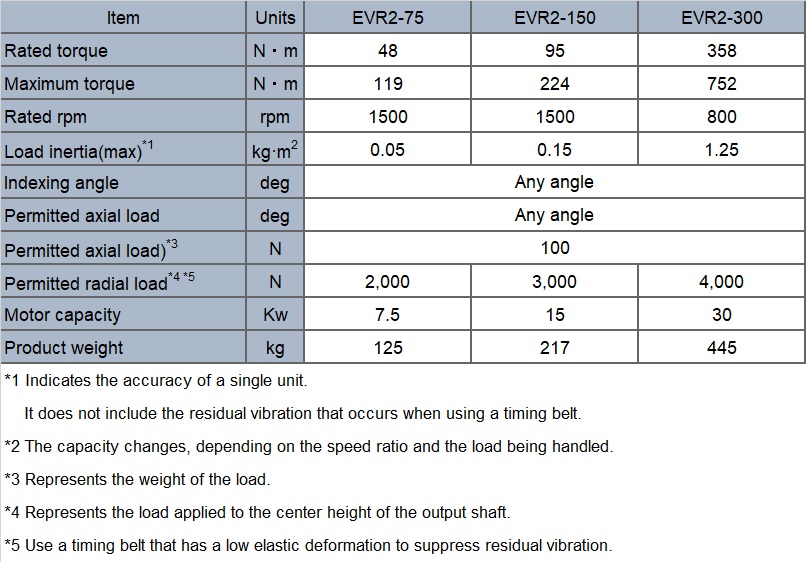

EVR2 Series (Indexing / Skewing drive system for rotating motor core)

Servo-dex EVR2 Series

The Servo-dex EVR2 series is an indexing/skewing drive system for rotating the electric motor cores used in home appliances. It is optimal for electric motor core production press lines that make motors for home appliances, such as air conditioners and general-purpose motors. It reduces mold maintenance by suppressing vibration when stopping a workpiece with high-precision positioning.

This series can easily be controlled using a timing signal, and various control patterns are now also available.

This series can easily be controlled using a timing signal, and various control patterns are now also available.

Features

General-purpose models providing basic performance at a low cost

Sandex Series (Indexing for laminated motor core)

This cam-actuated indexer is used to lamiated motor core. It uses our VSD for a non-mechanical, compact, servo-drive system that synchronizes with the principle axis?in this case, the press crankshaft. High-speed and precise motion is ensured by using a cam mechanism for the rotating motion, and a servomotor for synchronized operation with the press. Sankyo offers a lineup of indexers for laminated motor core.

Features

- High Reliability : Cam-actuated for motions with excellent reliability.

- Synchronized Operation : Features our servo-drive system developed specifically for synchronized operation.

- Easy to Install : Easily installs on any press without timing belts or drive shafts.บ

.jpg)

+66-(0)2-516-5355

+66-(0)2-516-5355