Sandex

The Sandex series of indexers are based on the roller gear cam mechanism, a simple combination of a globoidal cam and cam followers. The profile of the cam and the rolling contact surfaces of the cam followers allow unrestricted development of various motions.

Sankyo began researching and developing the roller gear cam mechanism in 1970, when it launched the first Sandex indexer. The Sandex offers greater speed, rigidity, output torque, and has no backlash, unlike other mechanism. Customers continue to choose Sandex when they need a dependable rotary positioning device.

Our mainstream drives either index or oscillate, but the same motion control principle drives our other products as well, such as our Pick and Place Units and Parts Handlers, which combine linear and vertical motions.

Sankyo began researching and developing the roller gear cam mechanism in 1970, when it launched the first Sandex indexer. The Sandex offers greater speed, rigidity, output torque, and has no backlash, unlike other mechanism. Customers continue to choose Sandex when they need a dependable rotary positioning device.

Our mainstream drives either index or oscillate, but the same motion control principle drives our other products as well, such as our Pick and Place Units and Parts Handlers, which combine linear and vertical motions.

Product Line

ECO Series (Shaft and flange type)

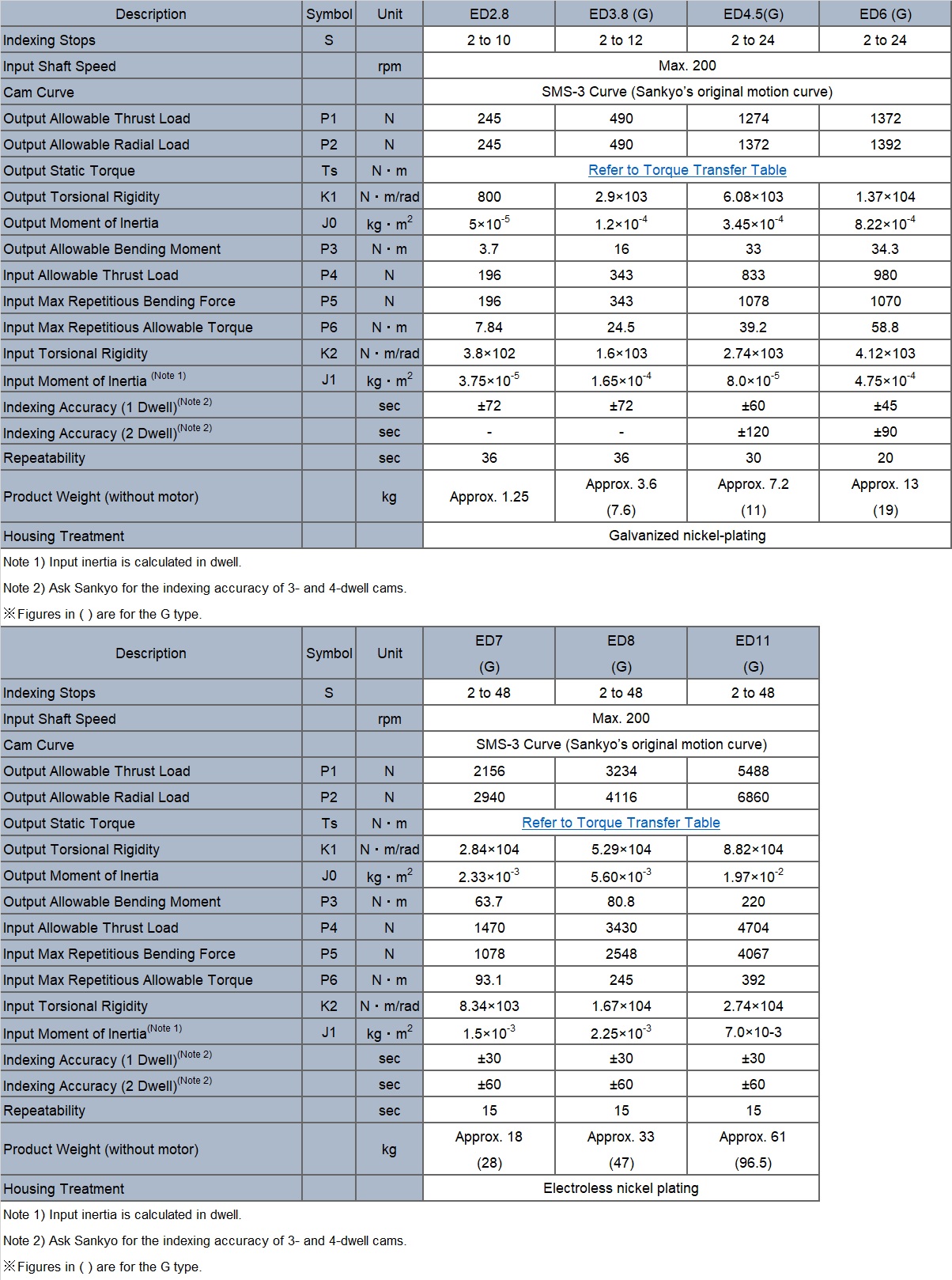

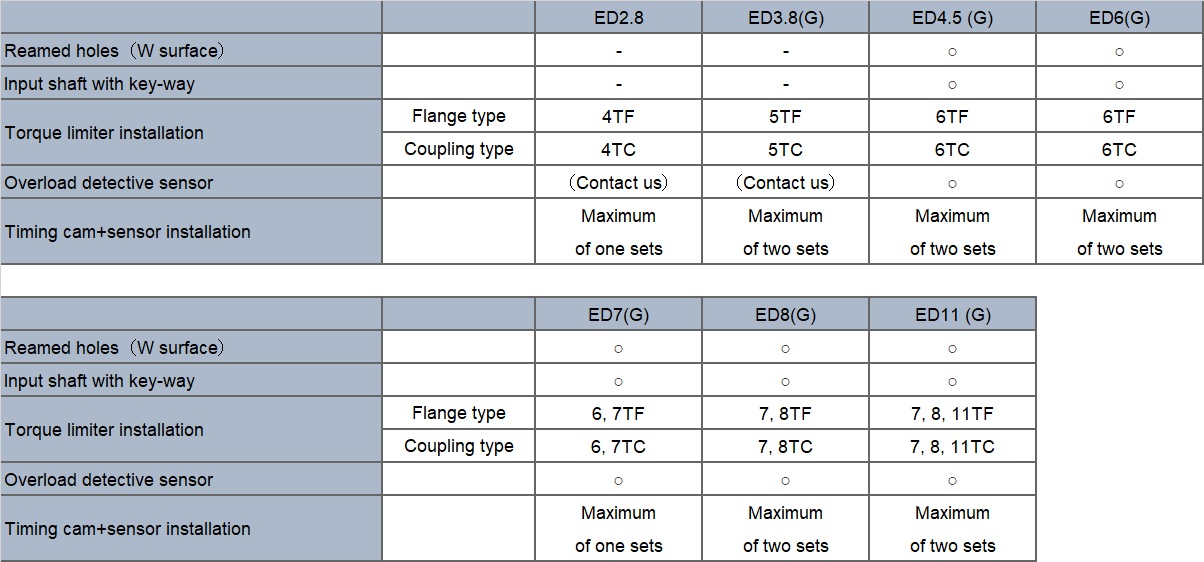

The ED Series represents a new concept for motion control units, combining cam and motor control technology into a small footprint.

This revolutionary concept delivers accuracy and flexible performance in a tightly integrated package.

The ED series allows you to program a cam indexer with flexible, stable motion patterns with the same ease of controlling a motor.

The package is perfect for benchtop production lines without using excessive drive equipment.

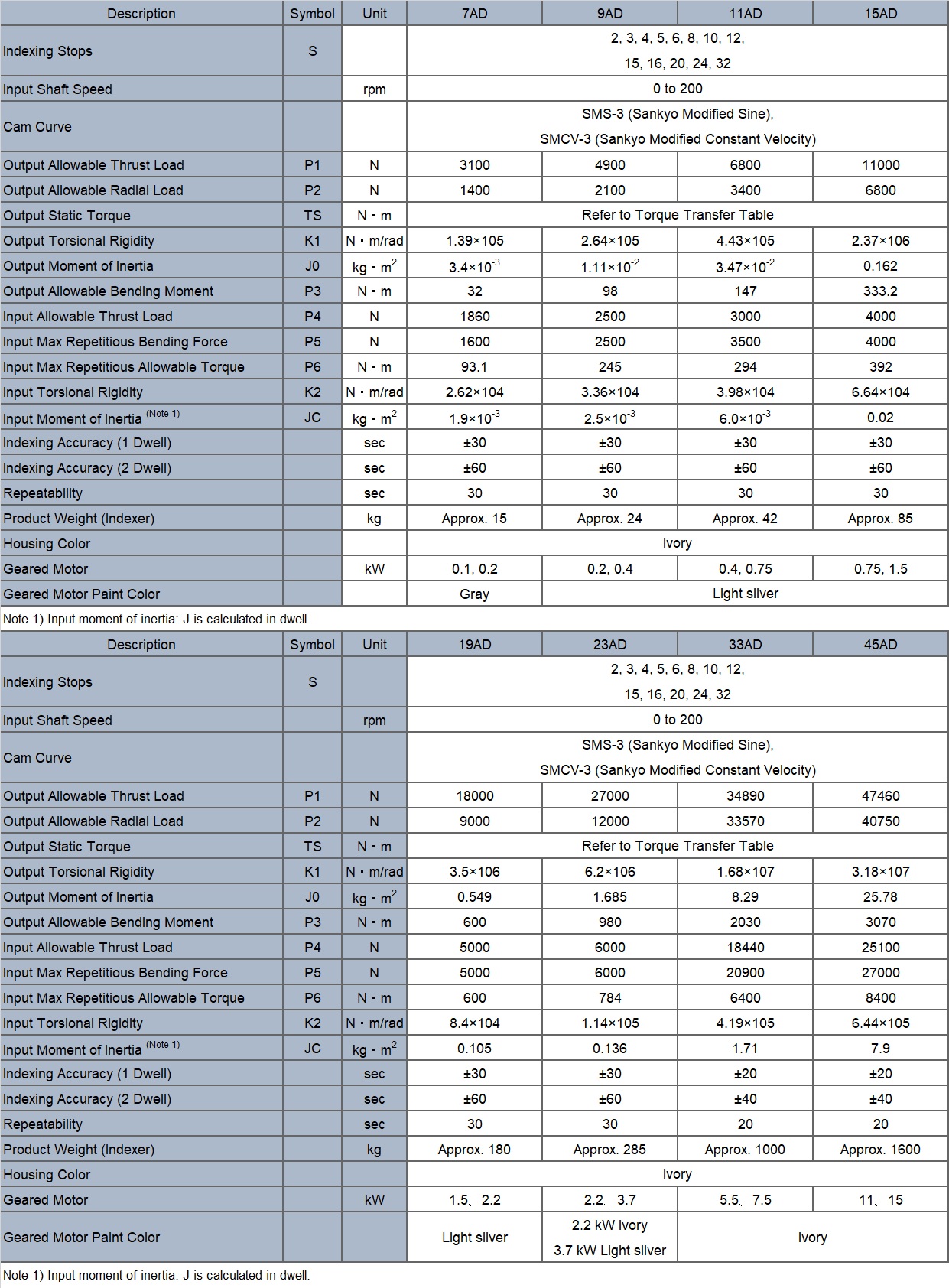

Alpha Series (Table type)

The Alpha Series is an all-in-one indexing drive package complete with a cost-effective shaft-mounted gearmotor on a low-profile housing.

After reviewing the design, this indexing drive has been made more user-friendly by building

on the roller gear cam mechanism found in all of our SANDEX products, which have set high production records.

Features

- Flange Output : Dials, gears, sprockets, and other elements can be mounted directly to the output shaft.

- Wide Product Lineup : Available in many sizes and indexing configurations.

- High Rigidity : Flange output surface stays rigid in all directions.

- Compact : Thin profile housing

- Standard Equipped Gearmotor : The Alpha Series come with a variable frequency drive gearmotor with a hollow output shaft.

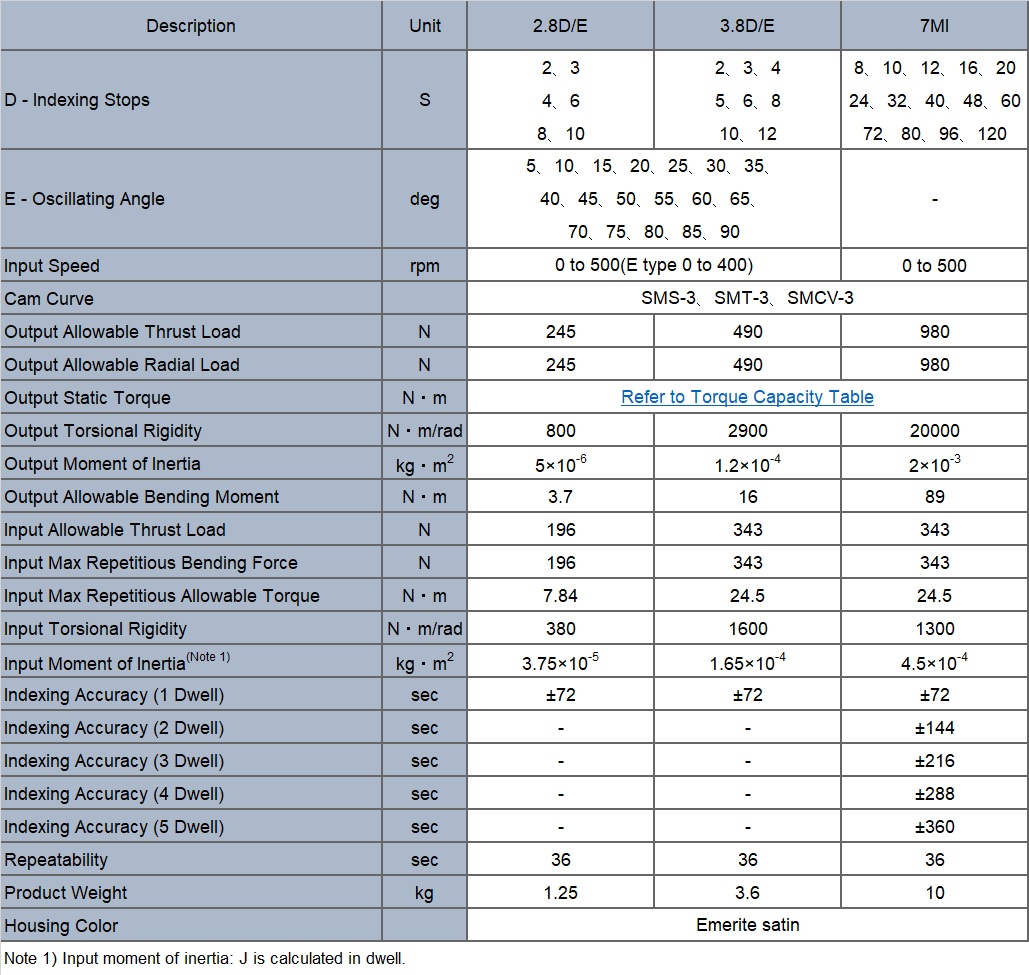

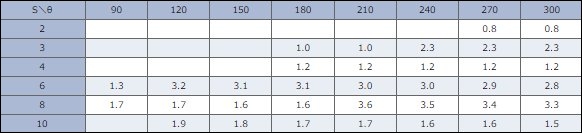

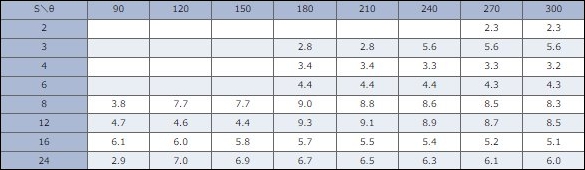

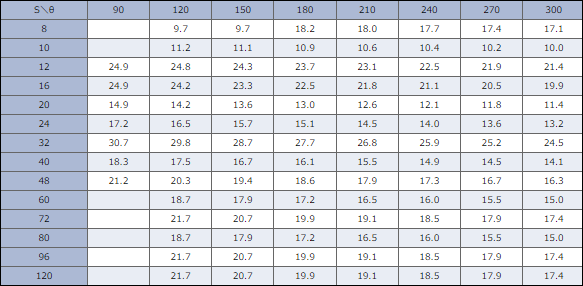

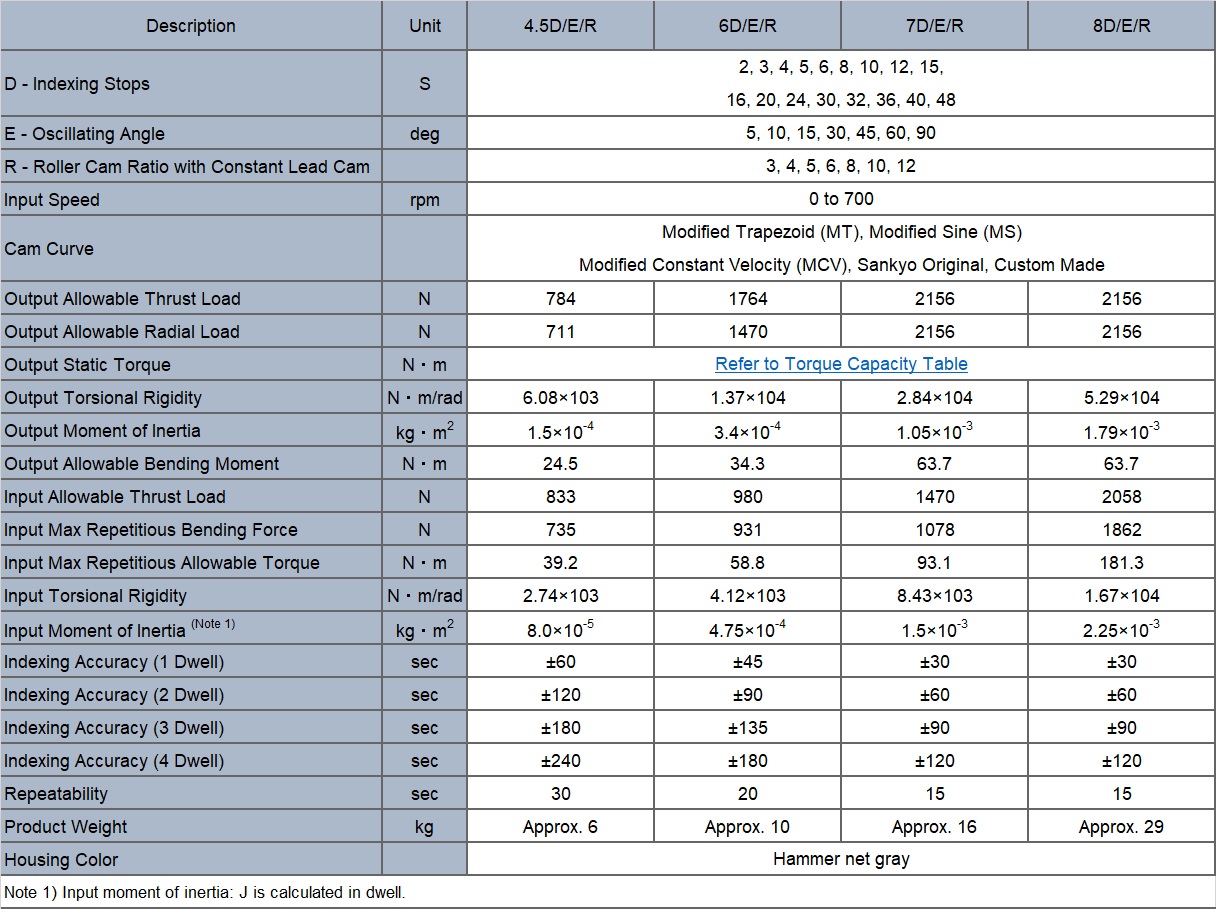

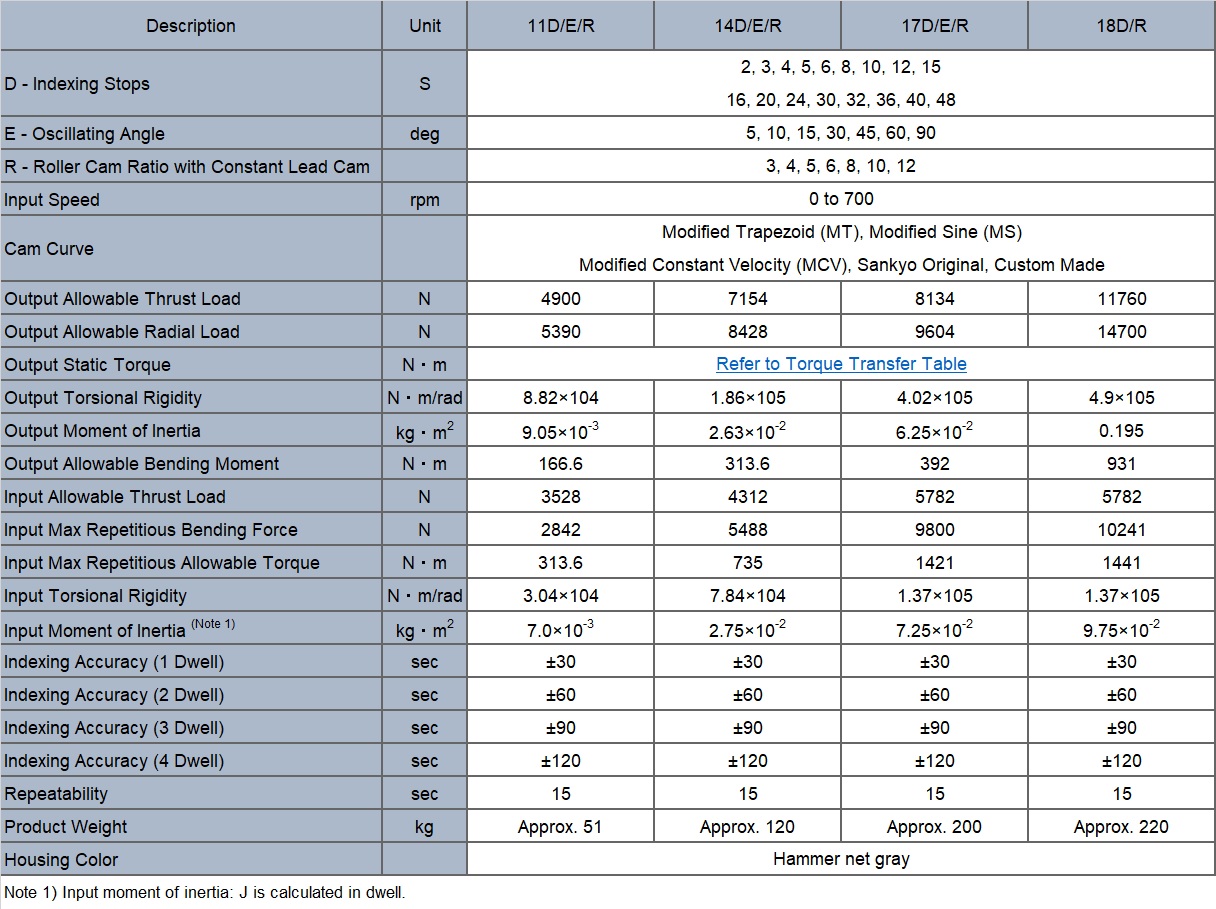

Alpha Series Specifications

D,MI Series (Miniature type)

Features

- Wide Product Lineup : Available in many sizes and indexing configurations.

- High Speed : High speed input (700 rpm)

- High Efficiency : Low frictional torque reduces hysteresis loss.

- Flexible Mounting Positions : Index mounts in any position with gearmotor mounting on either side of the index

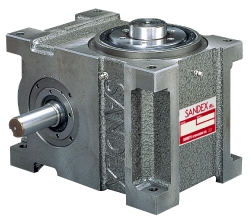

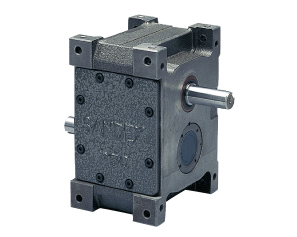

D Series (Shaft type)

Features

- Wide Product Lineup : Available in many sizes and indexing configurations.

- High Speed : High speed input (700 rpm)

- High Efficiency : Low frictional torque reduces hysteresis loss.

- Flexible Mounting Positions : Index mounts in any position with gearmotor mounting on either side of the index.

DF Series (Flange type)

This drive features a highly rigid output shaft with a flange mounting surface for directly mounting tables, gears, and sprockets. This type features a “user-friendy” design that allows you to place a large bore through-hole in the center of the output shaft and then attach a fixed shaft to the center of the output shaft, or attach peripheral equipment for indexing drives.

Features

- Flange Output : Dials, gears, sprockets, and other elements can be mounted directly to the output shaft.

- Wide Product Lineup : Available in many sizes and indexing configurations.

- High Speed : High speed input (700 rpm for models 4.5DF to 25DF)

- High Rigidity : Flange output surface stays rigid in all directions.

- Flexible Mounting Positions : Index mounts in any position with gearmotor mounting on either side of the index.

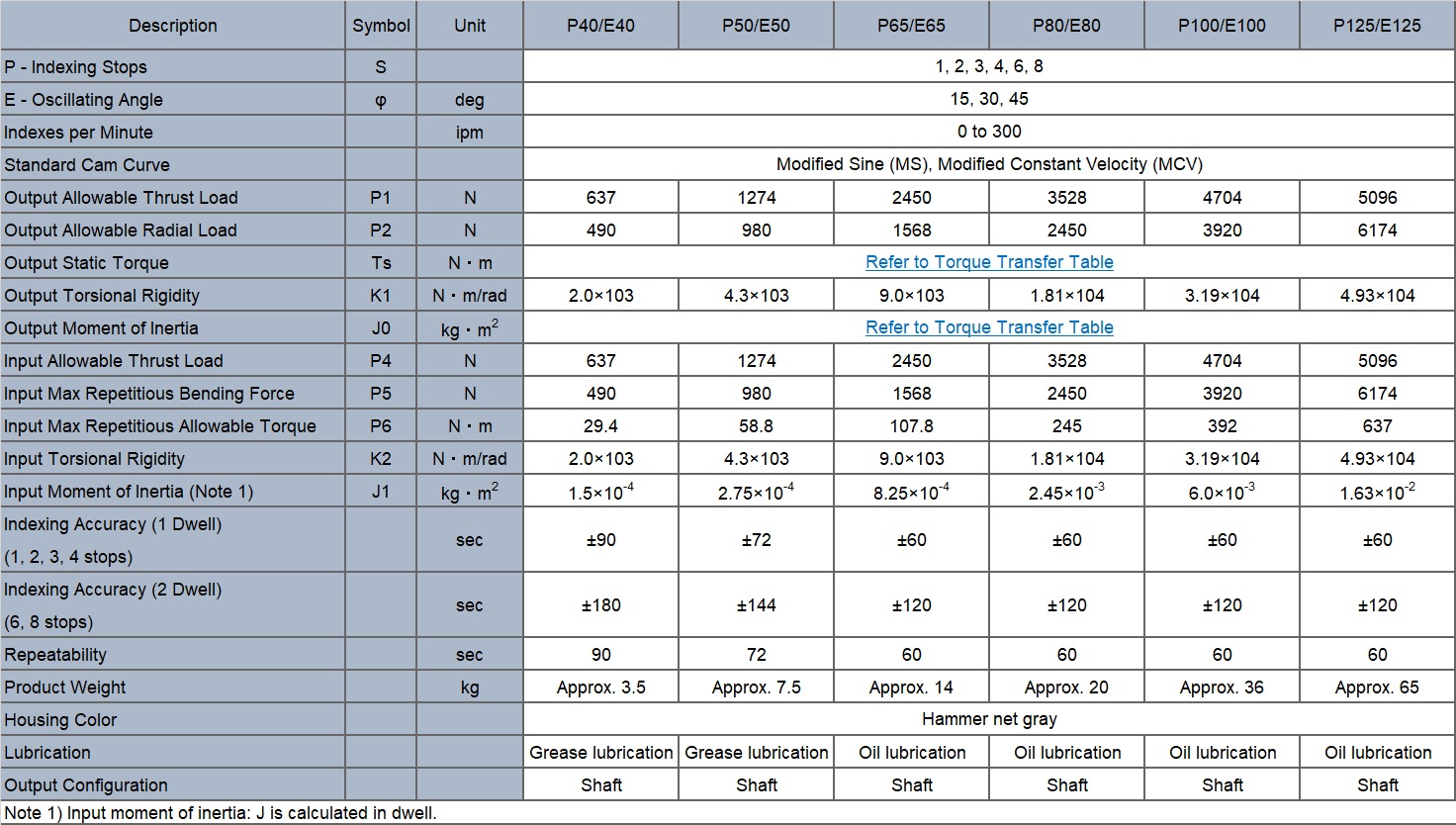

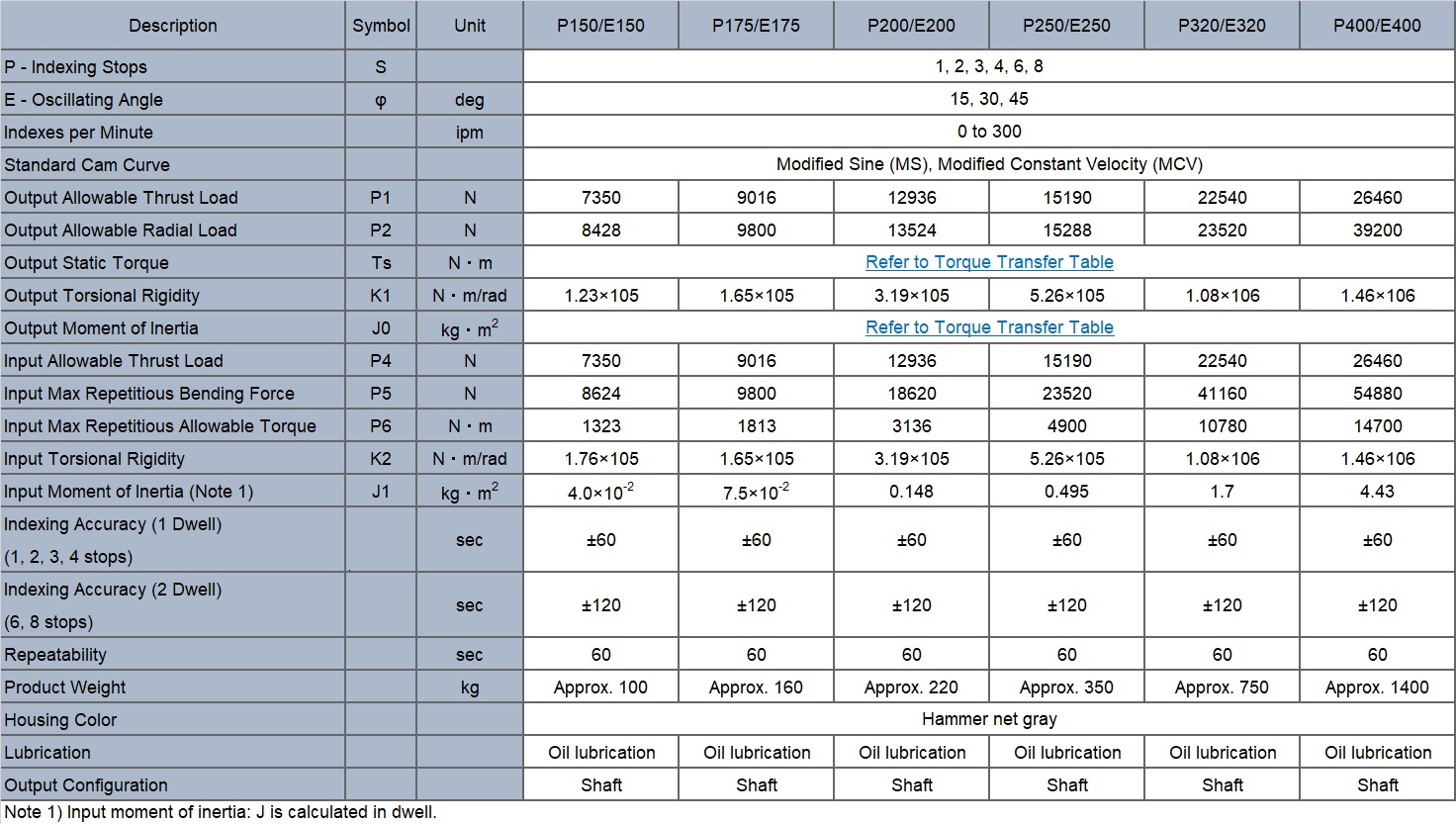

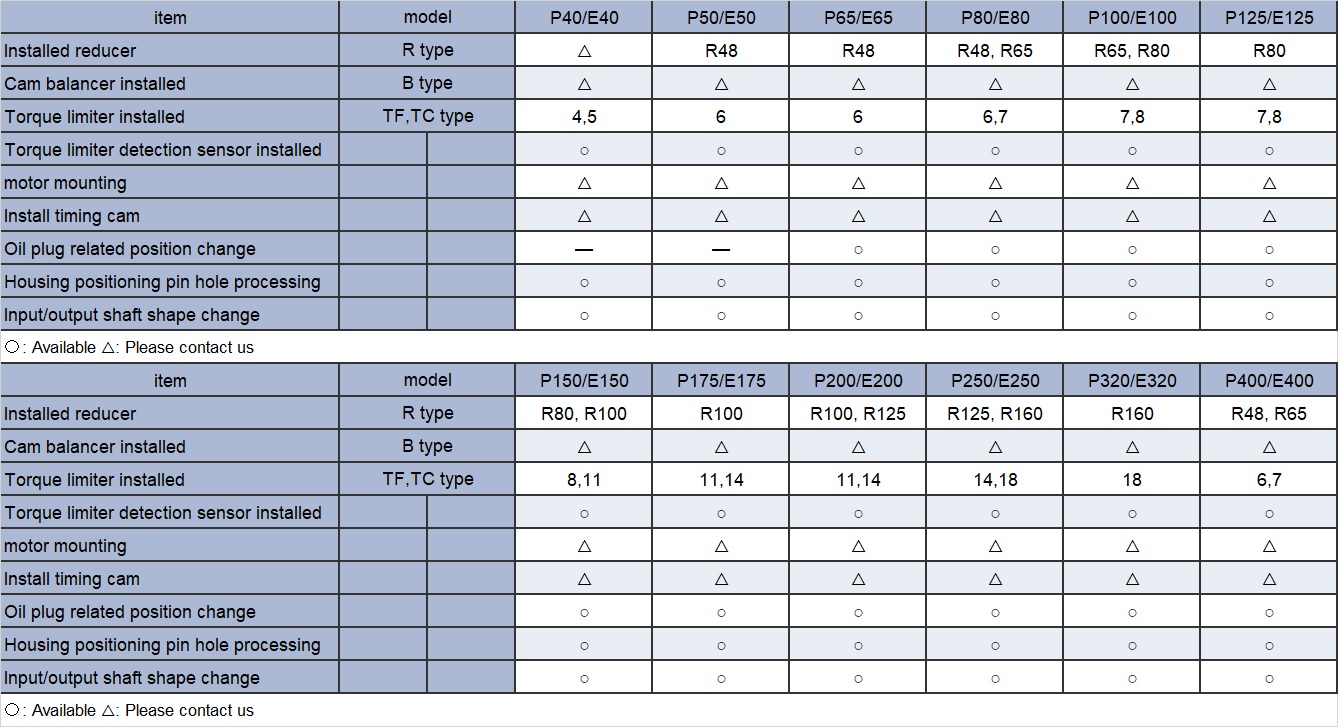

P Series (Parallel cam type)

Features

- Parallel Shaft Type : Unlike other SANDEX indexers, the input and output shafts on a P Series indexer are parallel.

- Wide Product Lineup : Available in many sizes and indexing configurations.

- Suitable for a Small Number of Stops. : Units can be made from one indexing stop.

- Flexible Mounting Positions : Index mounts in any position with gearmotor mounting on either side of the index.

Rotate Applications

Supply and Discharge Welding Materials

Synchronized Pick & Place and Dial

2.5-stop Indexing Dial

Synchronized Operation off Single Driveshaft

Coil Winding

Workpiece Inversion

Center Column Indexing Drive

Central-mounted Work Units

Large-scale Fixture Turning

Work Unit Mounted using Hollow Center Shaft

Linear Applications

Transfer Feeding Mechanism

Transfer Feeding Mechanism for Bar Stock

Upright Conveyor

Screw Conveying

Variable Feed Pitch for Sheet Stock

Transfer Applications

Overhead Parts Transferring Mechanism

Distribution to Two Lines

Conveying with Presence-detection

End-to-end Conveyor Transfer

Parts Conveying by Pushing

Corner Pusher for Supplying Parts

Pick and Place Control

Pick and Place Control with Intermediate Stop

Disk Conveyor

Parts Feeding using an Oscillating Arm

Syncronize Applications

Synchronized Vision Inspection

Product Inspection

.jpg)

.jpg)

.jpg)

.jpg)

+66-(0)2-516-5355

+66-(0)2-516-5355