MachineTools

Our machine tool products include a rotary table, automatic tool changer, pallet changer, and an indexable tool post. Each product contributes to the machine tool's performance by adding functionality, reducing cycle times, and improving machining quality.

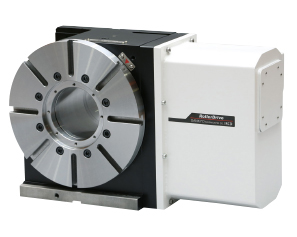

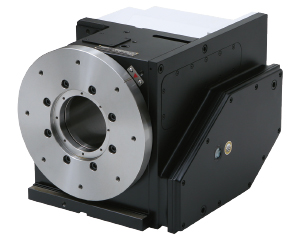

The rotary table features a solid price cross-roller bearing and output shaft that machine tool manufacturers like because it delivers runout-free rotation, high rigidity,zero backclash,precision dynamic rotary indexing, and clamp free position holding. Roller Drive technology eliminates backlash and holds positions without clamping. The table supports both high-speed cutting and continuous heavy cutting with sustainable quality and accuracy, while saving energy by eliminating hydraulic clamping support.

We also offer a rotary table with a second tilt axis that gives 5-axis machining functionality to existing mahine centers.

The rotary table features a solid price cross-roller bearing and output shaft that machine tool manufacturers like because it delivers runout-free rotation, high rigidity,zero backclash,precision dynamic rotary indexing, and clamp free position holding. Roller Drive technology eliminates backlash and holds positions without clamping. The table supports both high-speed cutting and continuous heavy cutting with sustainable quality and accuracy, while saving energy by eliminating hydraulic clamping support.

We also offer a rotary table with a second tilt axis that gives 5-axis machining functionality to existing mahine centers.

Product Line

RCD Series (Standard model)

The RollerDrive CNC RCD Series is a circular table designed to meet the requirements of machine tool manufacturers for greater speed and accuracy.

The RCD Series uses Sankyo's zero-backlash reducer, the RollerDrive to deliver output motion unaffected by external disturbances, unlike gearmotors or torque motors.

The high accuracy and rigidity afforded by the zero-backlash technology gives the RCD Series its high rotary positioning accuracy 10 seconds maximum, and the ability to hold up to heavy cutting of hard steel.

The RCD Series uses Sankyo's zero-backlash reducer, the RollerDrive to deliver output motion unaffected by external disturbances, unlike gearmotors or torque motors.

The high accuracy and rigidity afforded by the zero-backlash technology gives the RCD Series its high rotary positioning accuracy 10 seconds maximum, and the ability to hold up to heavy cutting of hard steel.

Features

Permanent accuracy

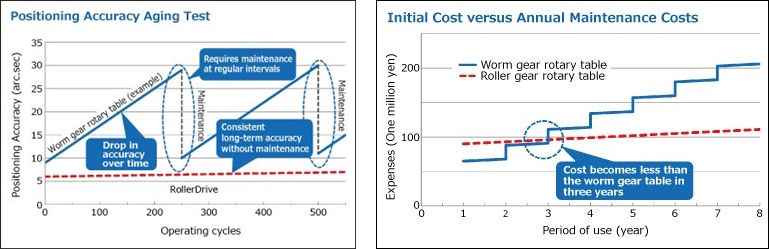

By adopting our roller drive mechanism, there is no deterioration in the internal parts of the RCD Circular Table and its accuracy does not deteriorate after long-term use. It has excellent durability. No routine calibration or adjustment work is required.

Excellent performance characteristics due to the zero-backlash design

With our roller drive mechanism, it is possible for repeated output operations to be equally precise, without being disturbed by external forces. Because it achieves high-precision positioning with a rotational accuracy of 10 seconds or better, it can also be used for heavy cutting on hard steel.

No clamp operation

Since the roller drive CNC has zero play due to its design, it does not require any clamping operations. With this design, clamping and unclamping time is effectively eliminated and no other energy source is need, unlike conventional hydraulic systems.

By adopting our roller drive mechanism, there is no deterioration in the internal parts of the RCD Circular Table and its accuracy does not deteriorate after long-term use. It has excellent durability. No routine calibration or adjustment work is required.

Excellent performance characteristics due to the zero-backlash design

With our roller drive mechanism, it is possible for repeated output operations to be equally precise, without being disturbed by external forces. Because it achieves high-precision positioning with a rotational accuracy of 10 seconds or better, it can also be used for heavy cutting on hard steel.

No clamp operation

Since the roller drive CNC has zero play due to its design, it does not require any clamping operations. With this design, clamping and unclamping time is effectively eliminated and no other energy source is need, unlike conventional hydraulic systems.

No Maintenance and Excellent Price Performance

Example

Machine Tools

Automotive Parts

Die Casting

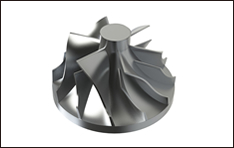

Impellor

Medical Parts

Die Cut Roll

Product Lineup

Standard type

6 models

6 models

Back mountiong type

5 models

5 models

Top mountiong type

5 models

5 models

RSR Series (Specialized for MC #30)

Features

Suitable for advanced automation.

Rotary joint 24+2 ports allows to select various clamp, cylinder, sensor, etc

Also sutable for multi-part machining of small parts

High productivity

High speed rotation : index 90°/0.46 sec

No clamp processing. Reduce non-processing time

Compact & lightweigt body

Capitalize on workspace of a smaller machining center

Save the allowable load and Capable of loading heavy jig and workpiece on table

Low-maintenace by RollerDrive mechanism

Accuracy is sustainable for a long term due to zero-backlash

Reduce machine dawntime. Regular maintenance is oil change only

Rotary joint 24+2 ports allows to select various clamp, cylinder, sensor, etc

Also sutable for multi-part machining of small parts

High productivity

High speed rotation : index 90°/0.46 sec

No clamp processing. Reduce non-processing time

Compact & lightweigt body

Capitalize on workspace of a smaller machining center

Save the allowable load and Capable of loading heavy jig and workpiece on table

Low-maintenace by RollerDrive mechanism

Accuracy is sustainable for a long term due to zero-backlash

Reduce machine dawntime. Regular maintenance is oil change only

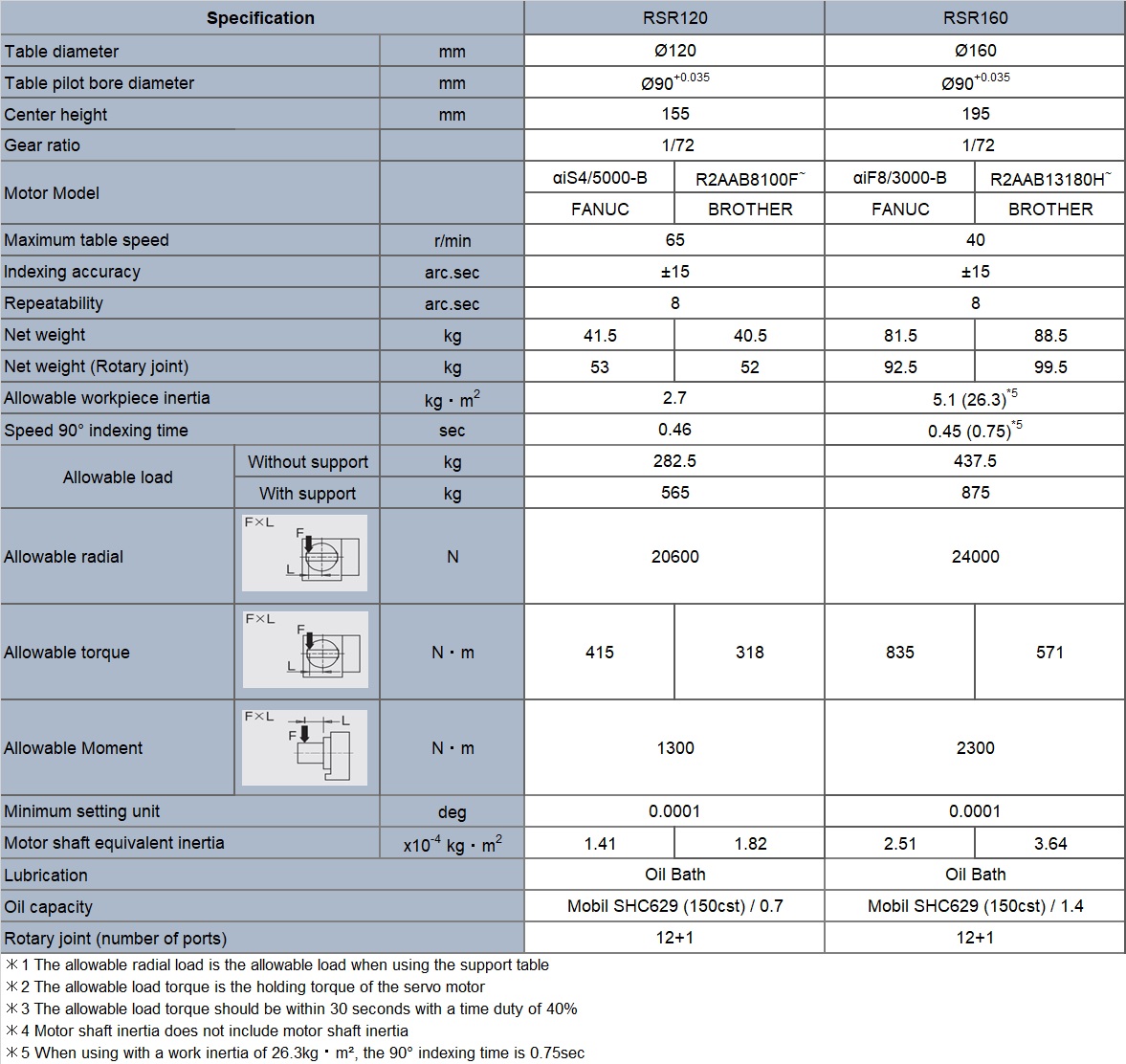

RSR Series Specifications

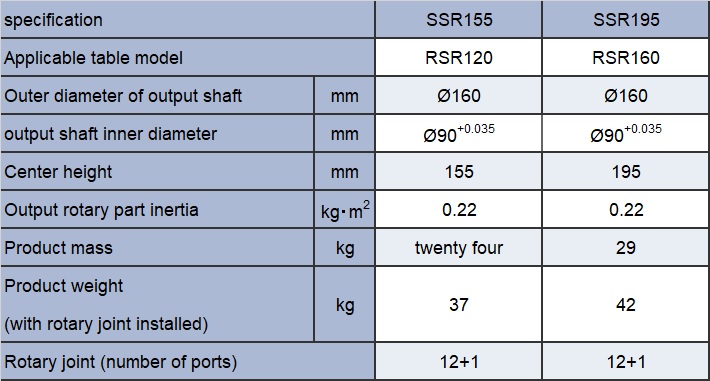

SSR Series Specifications

RS Series (Compact model)

Features

Permanent accuracy

By adopting our roller drive mechanism, there is no deterioration in the internal parts of the RCD Circular Table and its accuracy does not deteriorate after long-term use. It has excellent durability.

No routine calibration or adjustment work is required.

Excellent performance characteristics due to the zero-backlash design

With our roller drive mechanism, it is possible for repeated output operations to be equally precise, without being disturbed by external forces. Because it achieves high-precision positioning with a rotational accuracy of 10 seconds or better, it can also be used for heavy cutting on hard steel.

No clamp operation

Since the roller drive CNC has zero play due to its design, it does not require any clamping operations.

With this design, clamping and unclamping time is effectively eliminated and no other energy source is need, unlike conventional hydraulic systems.

By adopting our roller drive mechanism, there is no deterioration in the internal parts of the RCD Circular Table and its accuracy does not deteriorate after long-term use. It has excellent durability.

No routine calibration or adjustment work is required.

Excellent performance characteristics due to the zero-backlash design

With our roller drive mechanism, it is possible for repeated output operations to be equally precise, without being disturbed by external forces. Because it achieves high-precision positioning with a rotational accuracy of 10 seconds or better, it can also be used for heavy cutting on hard steel.

No clamp operation

Since the roller drive CNC has zero play due to its design, it does not require any clamping operations.

With this design, clamping and unclamping time is effectively eliminated and no other energy source is need, unlike conventional hydraulic systems.

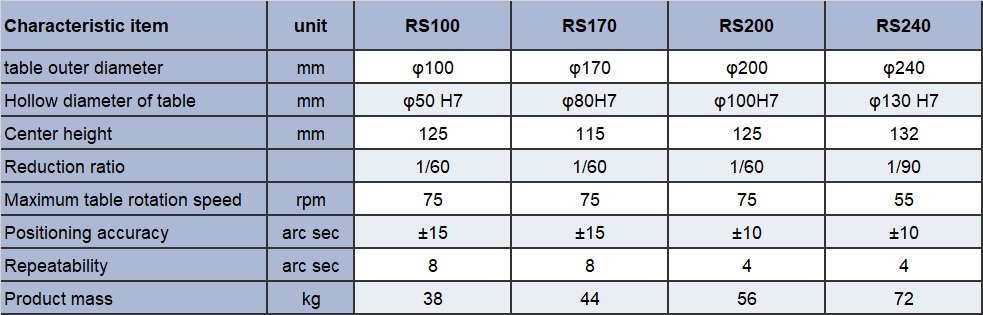

RS Series Specifications

Applications

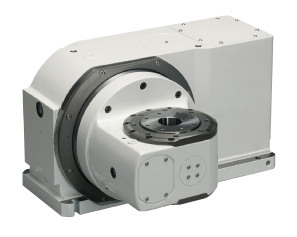

RT Series (Compact 2-Axis model)

Features

Unique

Compact opened design. Easy to use with loading system. Specialized for MC #30

High accuracy and High speed

High speed superior positional accuracy and repeatability.

Suitable for advanced automation.

Rotary joint 6 ports allows to select various clamp, cylinder, sensor, etc

Also sutable for machining complicated geometries

Compact opened design. Easy to use with loading system. Specialized for MC #30

High accuracy and High speed

High speed superior positional accuracy and repeatability.

Suitable for advanced automation.

Rotary joint 6 ports allows to select various clamp, cylinder, sensor, etc

Also sutable for machining complicated geometries

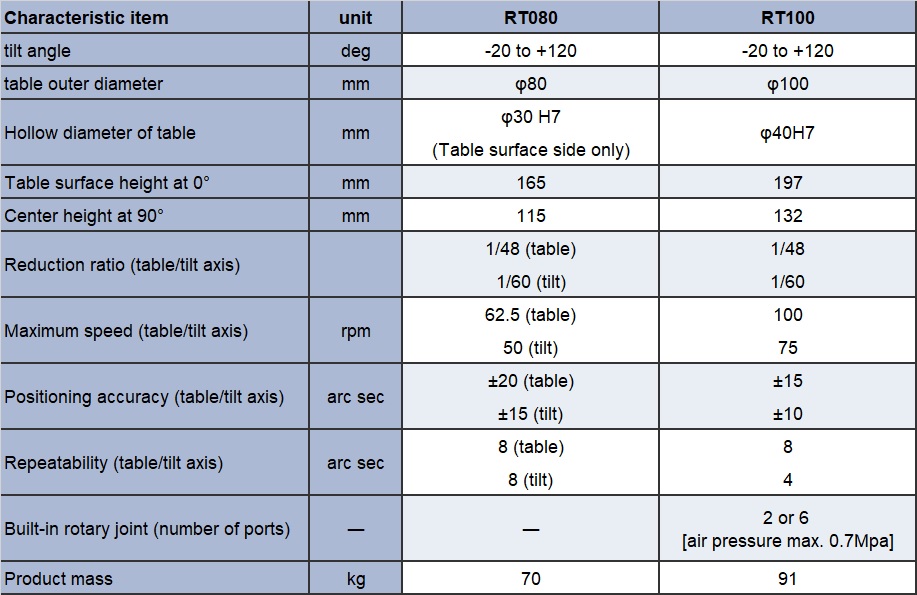

RT Series Specifications

Applications

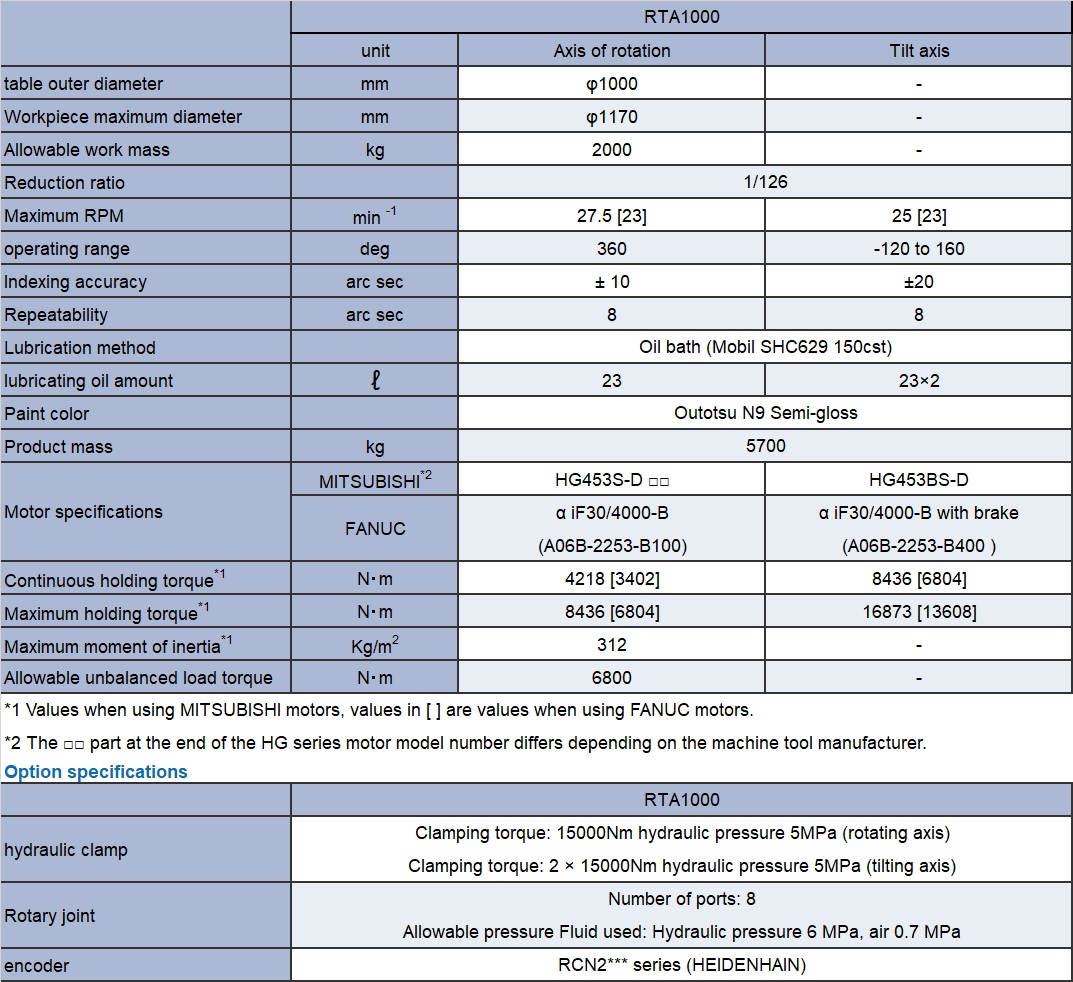

RTA Series (Dual-axis tilting circular table, large model)

RTB Series (2-axis model)

Features

Lightweight and compact design for installation on #30 machine

High-speed, high-response for smooth, high-rigidity rotation ideal for simultaneous multi-axis machining

Zero backlash with a structure highly resistant to unbalanced loads for clamp-free machining

Initial accuracy maintained even during extended use with no reduction in accuracy over time

High-speed, high-response for smooth, high-rigidity rotation ideal for simultaneous multi-axis machining

Zero backlash with a structure highly resistant to unbalanced loads for clamp-free machining

Initial accuracy maintained even during extended use with no reduction in accuracy over time

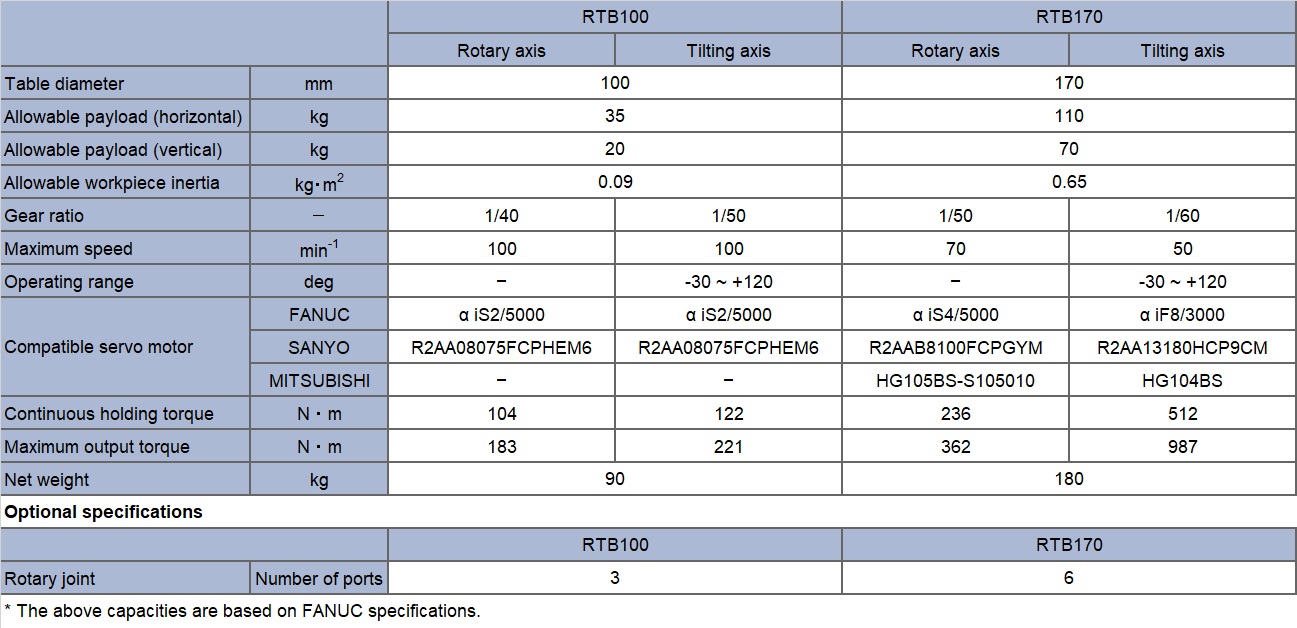

RTB Series Specifications

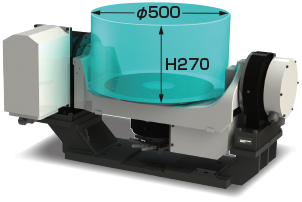

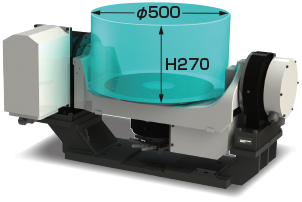

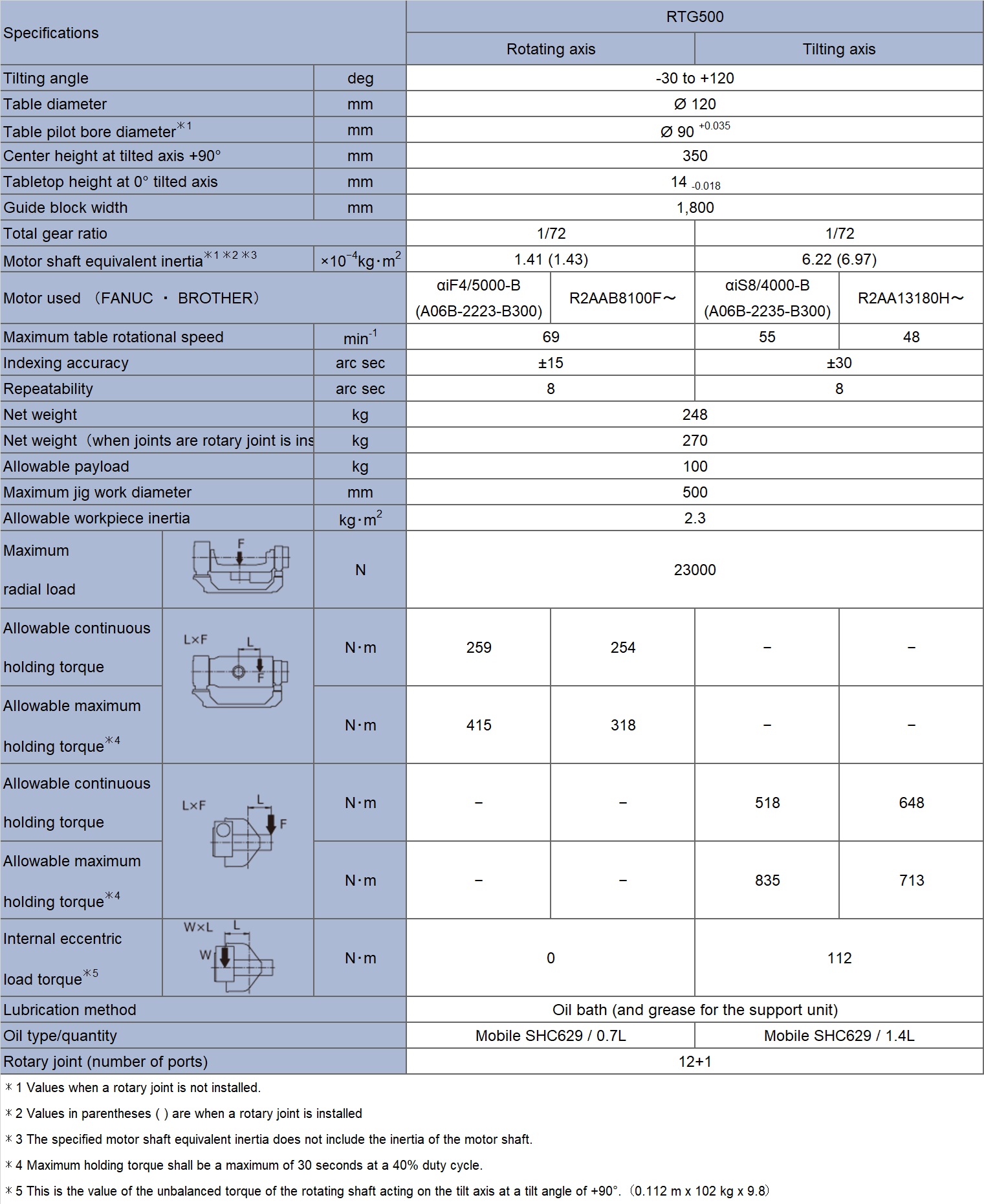

RTG Series (2-axis model)

Features

Built-in, no-backlash RollerDrive mechanism

Clampless processing drastically increases the ratio of cutting to non-cutting time

Lightweight and compact, and can be mounted on the #30 vertical MCs

Provides a large jig area of φ 500 x H270

Rotary joint is equipped with up to 12 + 1 ports

Routine maintenance is just an oil change, nothing else.

Clampless processing drastically increases the ratio of cutting to non-cutting time

Lightweight and compact, and can be mounted on the #30 vertical MCs

Provides a large jig area of φ 500 x H270

Rotary joint is equipped with up to 12 + 1 ports

Routine maintenance is just an oil change, nothing else.

.jpg)

+66-(0)2-516-5355

+66-(0)2-516-5355